Isopropyl alcohol, also known as isopropanol, plays a vital role in modern industrial cleaning processes. Its efficiency, versatility, and fast evaporation rate make it a trusted solvent in various sectors, from electronics to automotive maintenance and precision engineering.

Understanding Isopropyl Alcohol and Its Properties

Isopropyl alcohol (IPA) is a clear, colorless liquid with a mild odor. It is miscible with water, which allows it to effectively dissolve oils, residues and flux deposits. Industries often use IPA in concentrations between 70% and 99%, depending on the required cleaning power. The fast drying time prevents moisture build-up, thus reducing the risk of corrosion in sensitive equipment.

Note: Isopropyl alcohol is not the same as ethanol. Despite its name, it may resemble regular alcohol, but it has a different chemical structure and effects. Isopropyl alcohol is intended solely as a technical and cleaning fluid and is

Why Industries Rely on Isopropanol for Cleaning

Isopropanol is valued for its balance of safety and performance. It evaporates quickly, leaves no residue, and has strong degreasing properties. This makes it an ideal cleaner in environments where precision and cleanliness are essential. Factories, laboratories, and electronics assembly lines regularly use isopropanol-based formulations for surface preparation and equipment maintenance.

Key benefits include:

- Efficiently removes oils, adhesives and flux residues

- Dries without streaks or water spots

- Safe to use on most plastics and metals.

- Reduces contamination risks in sensitive production environments

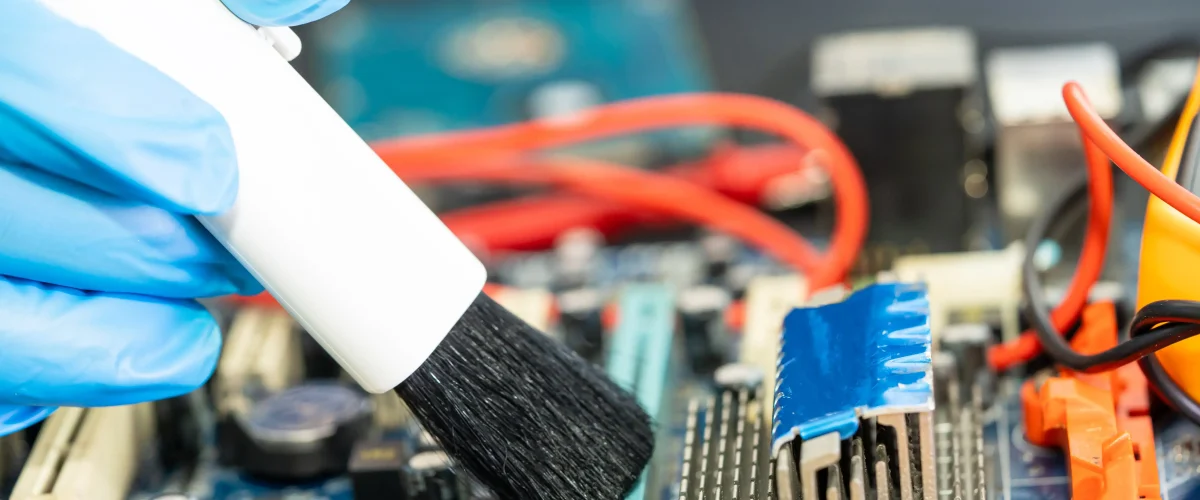

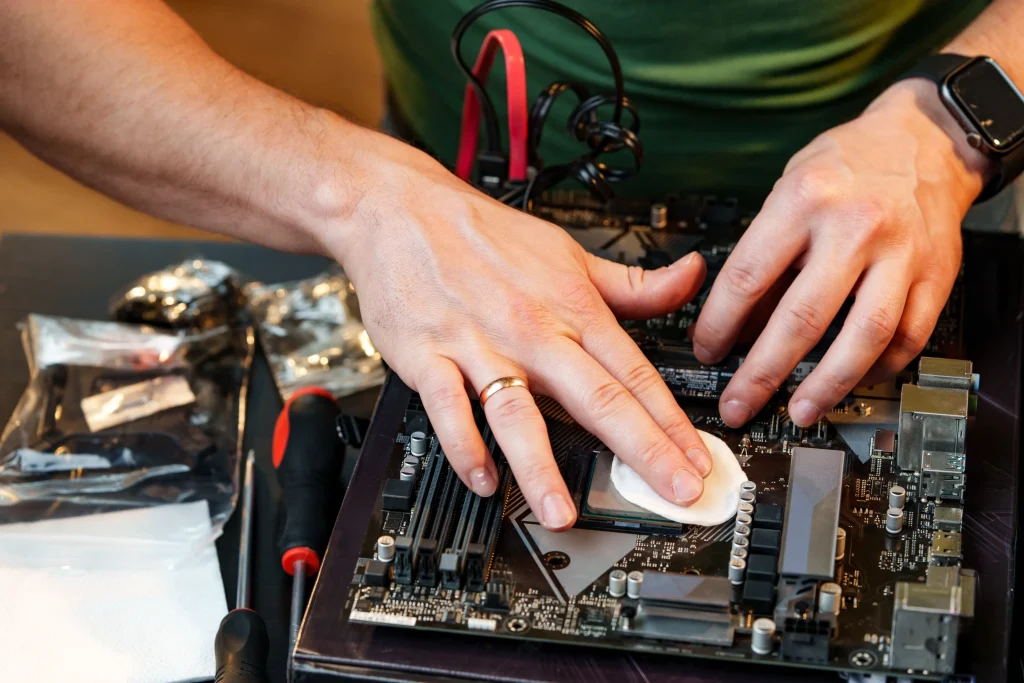

Removing flux and cleaning electronic components

One of the most common industrial uses of isopropyl alcohol is removing flux after soldering. If not cleaned properly, flux residue can cause corrosion or electrical leakage between connections. Isopropyl alcohol breaks down these residues and evaporates cleanly, keeping printed circuit boards reliable and contaminant-free.

For cleaning electronics, IPA is gentle enough to remove dust, dirt, and conductive debris without damaging delicate components. Whether you’re cleaning potentiometers or wiping connectors, the solvent’s non-conductive properties help prevent short circuits and static buildup.

Ridge Cleaner Liquid and surface cleaning

In addition to electronic cleaning, isopropyl alcohol serves as a ridge cleaner liquid in industrial environments. When used on production lines or tool surfaces, it removes fine residues left behind by machining oils or polishes. This step is essential before applying coatings, adhesives or paints to ensure good adhesion and finish quality.

Safety and environmental compliance

European industries attach great importance to worker safety and environmental protection. Isopropanol, when used correctly, meets these standards, as it has low toxicity compared to many alternative solvents. Proper ventilation, personal protective equipment (PPE), and safe storage practices ensure compliance with EU regulations on the handling of volatile organic compounds (VOCs).

From removing flux in electronics manufacturing to use as a ridge cleaner liquid in metalworking, isopropyl alcohol remains one of the most trusted cleaning agents available to industrial professionals . Its effectiveness, rapid evaporation and versatility make it indispensable in countless sectors.